Cranes and hoists are used extensively in industry and construction as a means to lift and place heavy loads. Many of these cranes and hoists are powered by electric motors with VFDs that allow for precision control of the load. Bonitron's drive accessories enhance VFD precision and reliability. A motor connected to a load will be either "motoring" or "overhauling". A motoring motor is converting electrical energy into mechanical energy to move the load. An overhauling motor is being driven by the load and is converting mechanical energy into electricity, acting as a generator.

- Maximize drive system efficiency and reliability

- Safely lower loads without tripping drives

- Utilize braking current to power other drives

- Backup power to protect from sags and outages

Braking/Overhauling

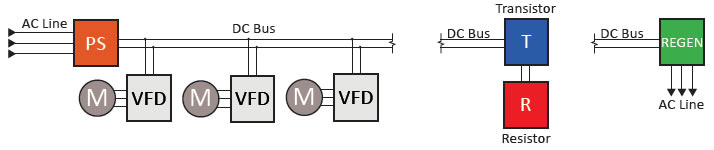

When a load is lowered, the motor acts as a brake, generating electrical energy which is dissipated by regen or transistor/resistor units.

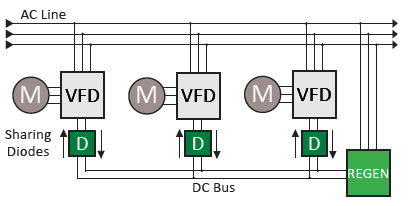

Power Sharing

Motors generating electricity while lowering a load can share power with other motors on a common DC bus.